We have an AOI solution for every business

Smart, scalable AOI solutions for every production line

Built for companies that want the best service at the best price. Simply connect directly to our neural network online.

Built for companies that demand maximum privacy. Everything runs locally, with no online connection to our neural network.

What are the differences between the solutions we offer?

Compare our solutions and choose the right one for your business

| Feature | AOI Online | AOI Offline | AOI API |

|---|---|---|---|

| Type | Cloud-based AOI service | Standalone AOI machine | Programmable inspection API |

| Ideal For | Prototyping, QA labs, remote teams | In-house production, secure sites | Integration into custom systems |

| Installation | All-in-one kit, internet needed | All-in-one kit, no internet needed | Your hardware + cloud access |

| Speed | ~7–18s per board * | ~5–18s per board | Similar, depends on integration |

| Accuracy | High (Deep Learning-based) | High (same neural network) | High (via same cloud engine) |

| Max PCBA size | 40×50 cms (15.75″ × 20″) | 40×50 cms (15.75″ × 20″) | Your hardware |

| Integration | Standalone with optional reporting | Standalone, PDF export, barcodes | Full API for automation |

| Scalability | By adding subscriptions and units | By adding units | By automating API usage |

| Maintenance | Minimal, auto-updates via cloud | Local maintenance, updates by USB | You maintain your system; we the AI |

| Pricing Model | Monthly/annual subscription | One-time purchase | Subscription-based |

| Footprint | Minimal, 70x60x45 cms (H×W×D) | Minimal, 70x60x45 cms (H×W×D) | |

| Conformal Coating UV Support | ✅ Optional | ✅ Optional | ❌ Not available via API |

| Barcode/ Datamatrix automatic ready | ✅ Yes. Automatic | ✅ Yes. Automatic | By client |

*depending on internet connection speed

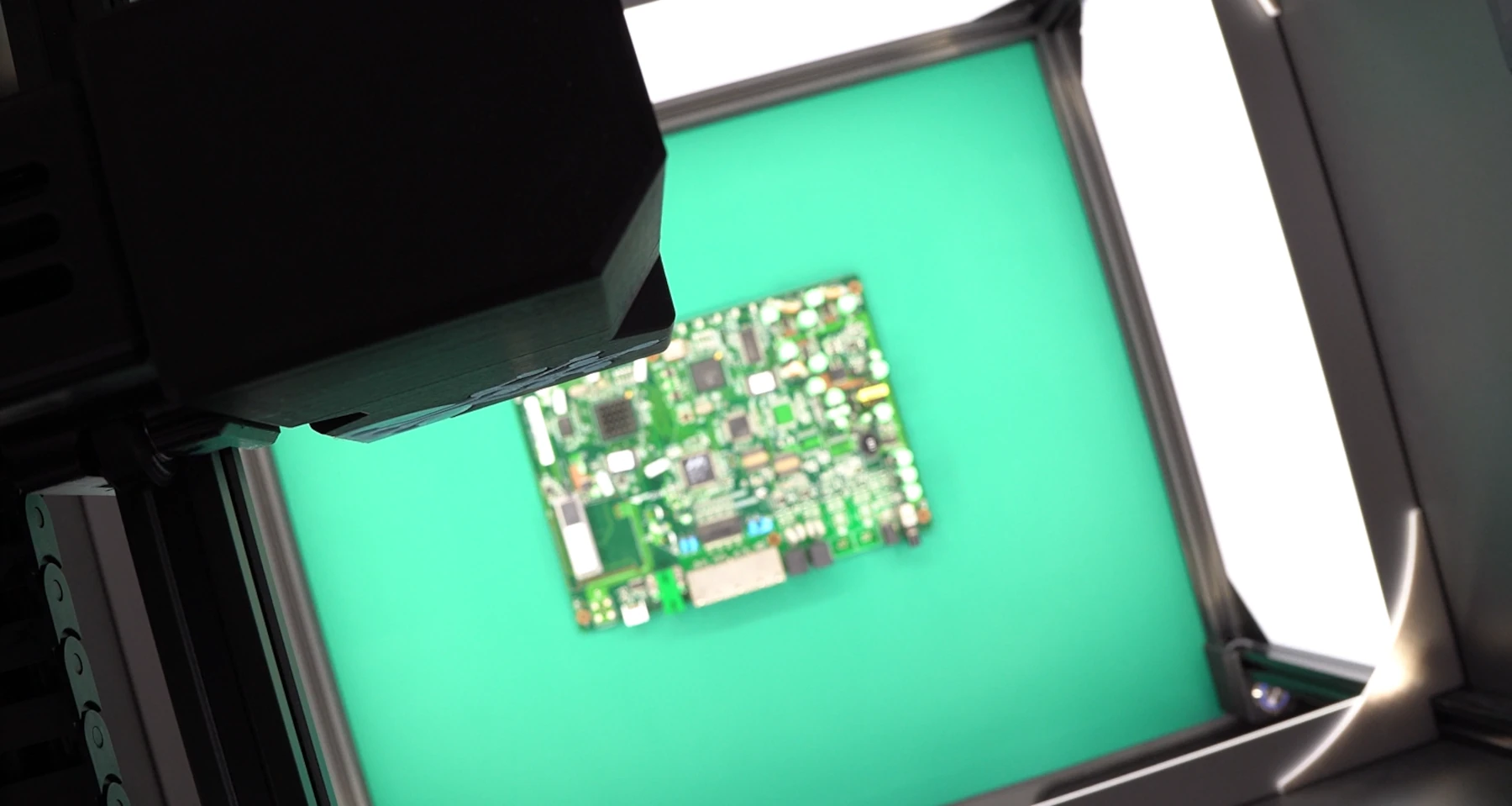

What our AOI can detect

Hover over the list to reveal and compare identified defects

- Displacements

- Non-presence

- Tombstones

- Short circuits

- Collisions between components

- Contamination

- Configuration

- Excesive rotation

- Wrong component

- Polarity errors

- Deformations in geometry

- Bent pins

What our AOI can detect

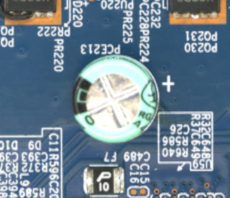

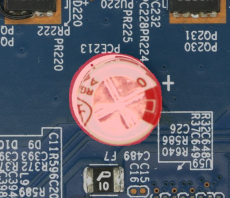

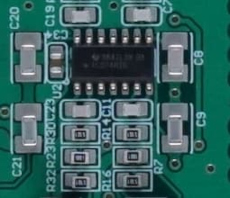

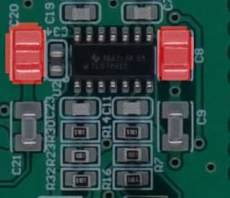

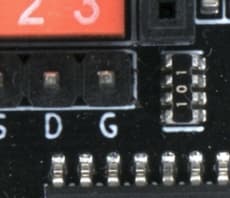

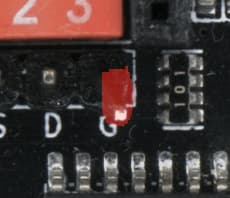

Visual comparison of identified defect detections

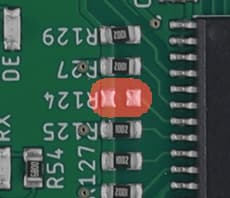

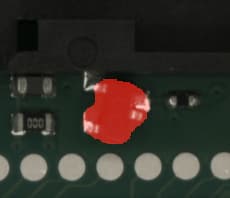

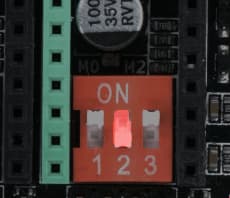

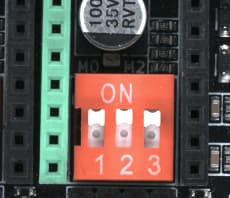

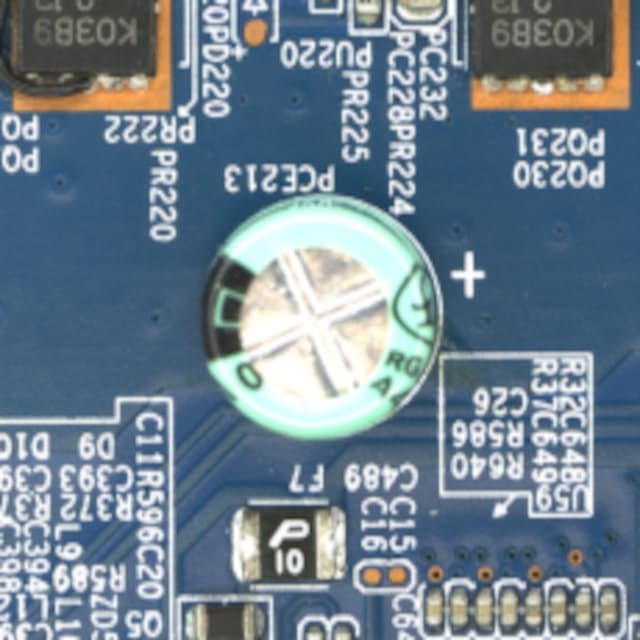

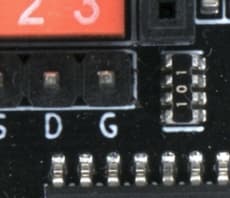

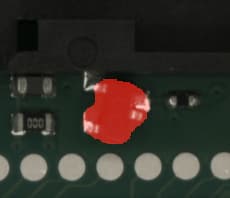

Displacements

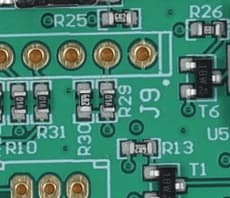

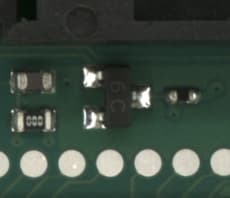

Non-Presence

Tombstones

Short circuits

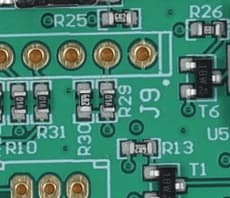

Collisions between components

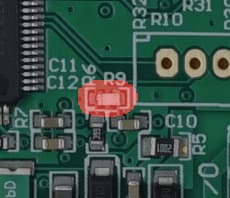

Contamination

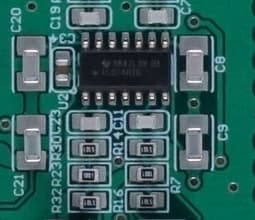

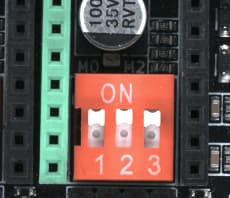

Configuration

Excesive rotation

Wrong component

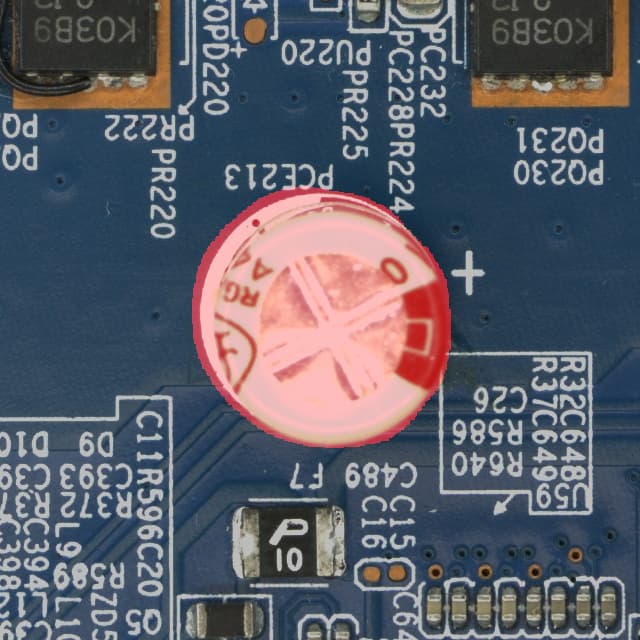

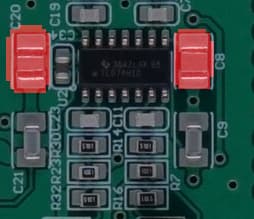

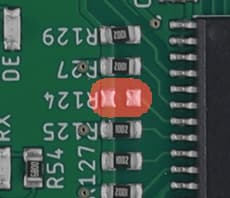

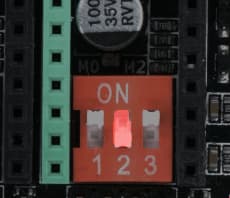

Polarity errors

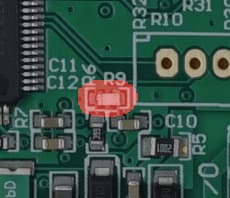

Deformations in geometry

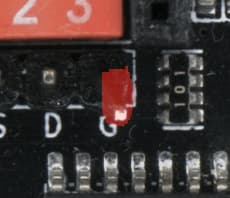

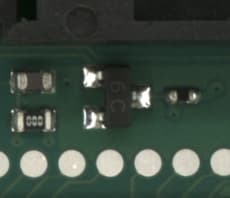

Bent pins

So which one is right for my business?

We are always ready to help you and answer your questions

If you need extra information about our products and services, get a trial account or want to rent an AgnosPCB AOI unit, please fill the following form.

Our support team will contact you as soon as possible.

USA

EUROPE

Hardware R&D and Test Office, 871 Harold Pl., Ste 112

San Diego, CA, 91914, United States info@agnospcb.com

PCTT Tenerife, C/Rectora María Luisa Salguero

Las Mantecas, 38320, Tenerife, España info@agnospcb.com

EUROPE - GERMANY

Munich

Michael Matauscheck michael@agnospcb.com